Product Center

-

-

Full Automatic Rebar Bolt Production Line

Product diameter: Φ16mm, Φ18mm, Φ20mm, Φ22mm, Φ25mm, special diameter products can be customized.

Product length: 1.2m ~ 3.0m. Products with special length can be customized.

Yield strength: 235mpa-600mpa, special strength products can be customized.

Single line production capacity: 260-300 units / h, double production for one driving two production lines (i.e. one material feeding line ......

-

-

Full Automatic Resin Capsule Production Line

The production line is formed by integrating multiple kinds of processing equipment, process pipelines and automatic control systems as well as mechatronics equipment including electric equipment, hydraulic equipment and pneumatic equipment. It absorbs the latest technical achievements at home and abroad, and features optimal design, scientific innovation and leading technology.

-

-

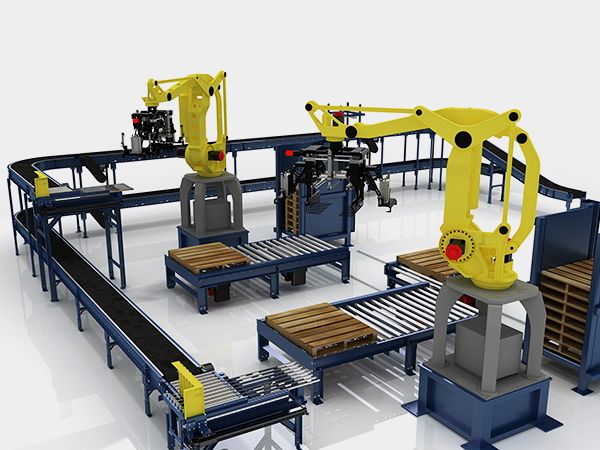

Intelligent Machine

The intelligent robot has the ability of accurate and stable transportation, high order, very simple structure, low failure rate, easy maintenance and repair. It can play the largest space in a narrow area. The whole central control room is adopted, and the large screen is simple and convenient to operate. Strong versatility: stacking and destacking of different goods can be completed by replacing

-

-

Semi-automatic Resin Anchoring Agent Production Line

The process gets rid of dirty, messy and poor working environments of medium-sized and small anchoring agent producers, and the danger of working with pressure vessel on the head. Using advanced foreign technologies as reference, it turns vertical arrangement into plane layout. Under the situation of the same output, it has the advantages of small floor area,

-

-

Advanced Mode

Equipment Name:Full automatic sausage sealant filling system-Advanced Mode

Model:RH-IX & CSK15-II

Equipment Introduction:

The system comprises three parts: hydraulic filling system, heat sealing and dosing system, and double-clipping system

The whole filling and packaging process has high degree of automation. The heat sealing tracks is firm and good-look.The clipping machine adopts advanced cli

-

-

Automatic sausage sealant filling machine-Serve Xllent

Automatic sausage sealant filling machine-Serve Xllent

-

-

Full automatic sausage filling system-medium mode

Equipment Introduction:

The system comprises three parts: hydraulic filling system, heat sealing and dosing system, and double-clipping system

The whole filling and packaging process has high degree of automation. The heat sealing tracks is firm and good-look.The clipping machine adopts advanced clipping technology, serve motor controlled, speed from:1-8,could be adjustable. You could find a best

-

-

Full-automatic Resin Putty Mixer

Model:MGJB750

Technical parameters

Voltage and power:φ3-380V/11Kw

Required air pressure:0.5~0.6Mpa

Spindle rotational speed:5~25 r/min

Material box capacity:750L

Overall dimension:1600*1550*2160

Product Features

Reasonable structure and reliable performance

The machine adopts double-shaft elliptical ratio spiral fan-shaped blade to radially stir materials, so that the stirring

-

-

Standard Mode

Standard Mode

-

-

Vertical Mode

In order to work with different viscosity materials, we innovated & developed the vertical filling style, which we believe it benefits more than the horizontal one. Adopt the electrical driven force instead of the hydraulic one, making the maintaining and trouble shooting more easier. Flexible filling head that you could choose from, which could help you to deal with different working capacity req

-

-

Automatic Curing Agent Mixer

Model:MGJB150

Technical parameters

Total power:1.5~2.2Kw

Spindle rotational speed:45~65 r/min

Overall dimension:1200mm*682mm*1060mm

Material box capacity:150L

Equipment Net weight:310Kg

冀ICP备12023966号-1 冀公安网备13010202001932号

冀ICP备12023966号-1 冀公安网备13010202001932号